It’s common for high performance structural components to experience some form of corrosion regardless of what type of material is used. Corrosion resistant coatings can increase the lifespan of a part, as well as reduce maintenance and replacement costs, but in order to select the appropriate coating it’s important to identify what kind of corrosion a part is prone to. Based on how a part is used and what conditions it’s exposed to, the kind of corrosion that develops may differ. There are five general types of corrosion: galvanic, stress cracking, general, localized and caustic agent corrosion.

Galvanic corrosion is extraordinarily common, and occurs when two metals with different electrochemical charges are linked via a conductive path. Corrosion occurs when metal ions move from the anodized metal to the cathode metal. In this case, a corrosion resistant coating would be applied to prevent either the transfer of ions or the condition that causes it. Galvanic corrosion can also occur when one impure metal is present. If a metal contains a combination of alloys that possess different charges, one of the metals can become corroded. The anodized metal is the weaker, less resistant one, and loses ions to the stronger, positively charged cathode metal. Without exposure to an electrical current, the metal corrodes uniformly; this is then known as general corrosion.

Stress-corrosion cracking (SCC) can seriously damage a component beyond the point of repair. When subjected to extreme tensile stress, a metal component can experience SCC along the grain boundary—cracks form, which are then targets for further corrosion. There are multiple causes of SCC, including stress caused by cold work, welding, and thermal treatment. These factors, combined with exposure to an environment that often increases and intensifies stress-cracking, can mean a part goes from suffering minor stress-corrosion to experiencing failure or irreparable damage.

General corrosion occurs as a result of rust. When metal, specifically steel, is exposed to water, the surface is oxidized and a thin layer of rust appears. Like galvanic corrosion, general corrosion is also electrochemical. In order to prevent oxidation, a preventative coating must interfere with the reaction.

Localized corrosion occurs when a small part of a component experiences corrosion or comes in contact with specific corrosion-causing stresses. Because the small “local” area corrodes at a much fast rate than the rest of the component, and the corrosion works alongside other processes such as stress and fatigue, the end result is much worse than the result of stress or fatigue alone.

Caustic agent corrosion occurs when impure gas, liquids, or solids wear a material down. Although most impure gases do not damage metal in dry form, when exposed to moisture they dissolve to form harmful corrosive droplets. Hydrogen sulphide is an example of one such caustic agent.

Corrosion Resistant Coatings

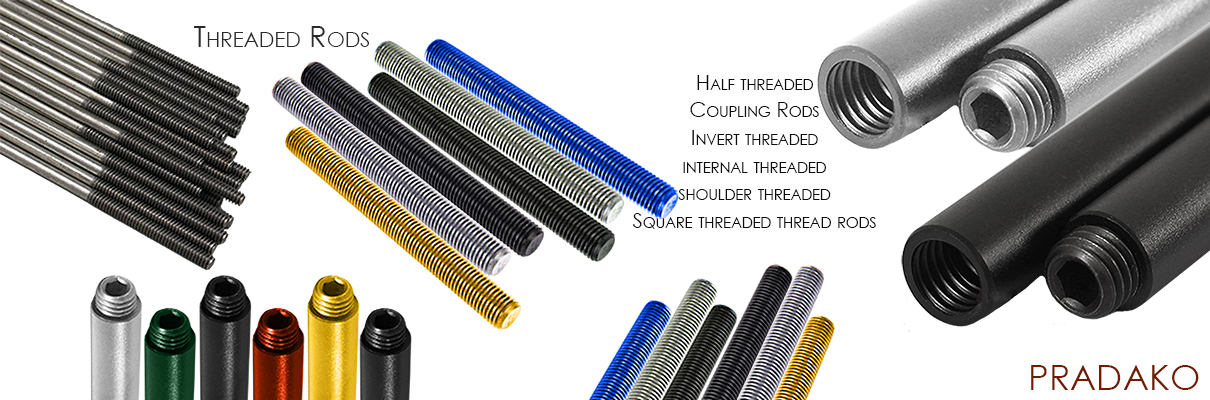

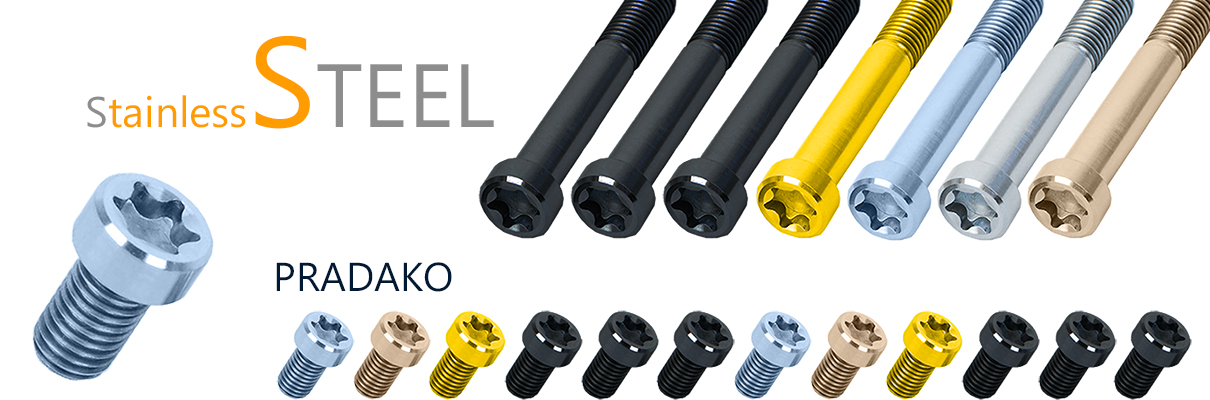

Corrosion resistant coatings for metal vary depending on the kind metal involved and the kind of corrosion prevention needed. To prevent galvanic corrosion in iron and steel alloys, coatings made from zinc and aluminium are helpful. Large components, such as bridges and energy windmills, are often treated with zinc and aluminium corrosion resistant coatings because they provide reliable long-term corrosion prevention. Steel and iron fasteners, threaded fasteners, and bolts are often coated with a thin layer of cadmium, which helps block hydrogen absorption which can lead to stress cracking.

In addition to cadmium, zinc, and aluminium coatings, often nickel-chromium and cobalt-chromium are often used as corrosive coatings because of their low level of porosity. They are extremely moisture resistant and therefore help inhibit the development of rust and the eventual deterioration of metal. Oxide ceramics and ceramic metal mixes are examples of coatings that are strongly wear resistant, in addition to being corrosion resistant.

PRADAKO Coatings:

Delta Coating (Zn Al flake Cr free Coating)

MetloK Coating (Yellow, Blue, Red)

AlomerCoating (White Coating)

Loctite Coating (Red, Black)

PRADAKO Plating’s:

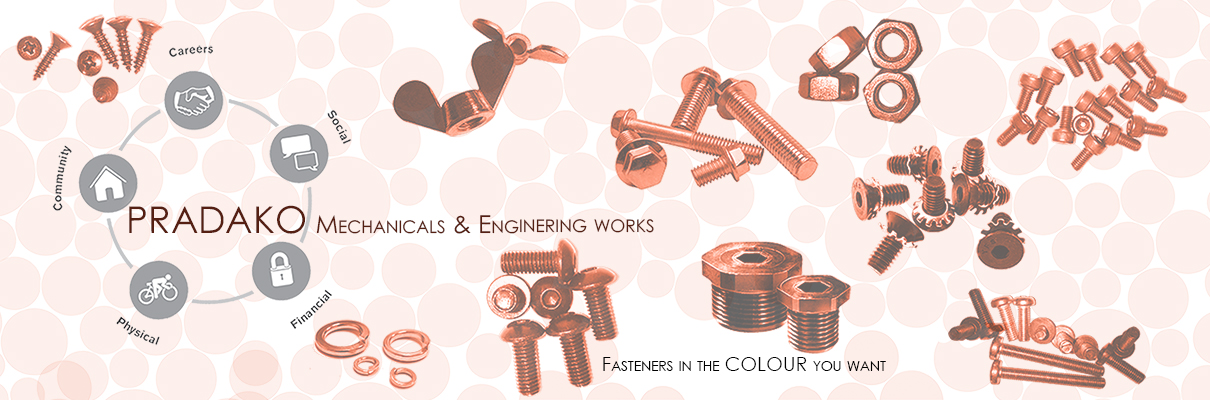

We offer a varied range of plating’s for our fasteners, some are concentrated on the aesthetics of the fasteners, some are for good life and some are meant for non-conductive applications.

| Trivalent Silver,

Trivalent Yellow, Trivalent Blue, Trivalent Black, Hexavalent Black, Hexavalent Yellow, Hexavalent Silver, White, |

Zinc Blue,

Zinc Black, Zinc Yellow, Copper, Nickel, Olive green, Black, ISO-White |

And if the customer has a different shade requirement or even different colour, is also possible depending on the size of the lot or requirement. On other side, it is possible with colours like RED, GREEN, ORANGE, BLUE, YELLOW, VIOLET, PLASTIC COLOURS, Brass plating, Gold plating, wooden patterns,etc.

PRADAKO is famous for its life in screws; we provide a wide range of thickness in coating and plating, which solely depend on the customer requirement of life of the fasteners and the place where they use PRADAKO fasteners.

We provide the plating and coating range from:

- Electro Plating:04-30 Microns; (Regular: 8-12 Microns)

- Galvanizing: 20- 70 Microns

- Powder Coating: 06-30 Microns

- Painting: 60 -150 Microns

- Spray Coating: 15-35 Microns

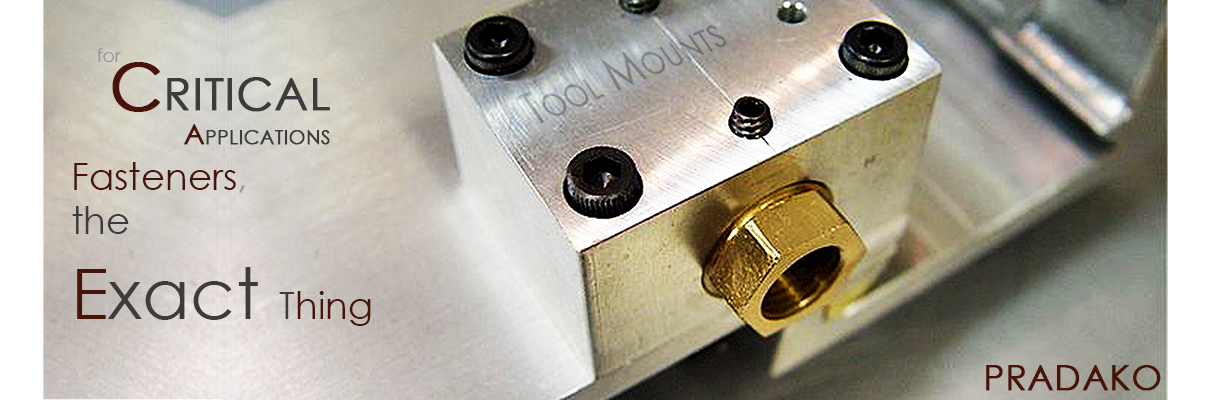

Life of Fasteners:

We give a great importance to the life of our fasteners no matter where they are used, and if the fasteners are been used with critical parts, we will make sure that even the parts get deteriorated but not our fasteners. The salt spray test hours we offer will astonish you, normally for machine parts fasteners, we offer 480 to 720 hours and for machine heart parts we offer 1000 to 1500 hours of salt spray.